Your cart is currently empty!

Tag: Oxygen Sensors

-

How Oxygen Sensors Work and How to Test replacement Oxygen Sensors

As a technician with years of automotive repair experience, I've found that faulty oxygen sensors are a common cause of abnormal fuel consumption and emissions issues.How Oxygen Sensors Work and How to Test replacement Oxygen Sensors.

-

can i replace oxygen sensor myself?

can i replace oxygen sensor myself?Yes, you can replace the oxygen sensor yourself. The process of replacing an oxygen sensor depends on the type of sensor you have and the make and model of your vehicle. However, in general, you will need to follow these steps: can i replace oxygen sensor myself you should see…

-

Are all oxygen sensors the same? What kinds of oxygen sensors are there

Oxygen sensors are vital components in modern automotive systems, playing a crucial role in maintaining engine performance and reducing harmful emissions. However, not all oxygen sensors are the same. In this article, we will explore the world of oxygen sensors, examining the different types available and their unique functions. The Importance of Oxygen Sensors Oxygen…

-

Functionality and Utilization of Oxygen Sensors

Today, automotive engines are governed by a variety of sensors, which play a crucial role in managing engine performance and emissions. When these sensors fail to provide accurate data, it can lead to various issues such as reduced drivability, increased fuel consumption, and emissions failures. One of the most vital sensors used in automobiles is…

-

12014 Premium original equipment oxygen sensors

12014 Premium original equipment oxygen sensors can bring benefits to 98 AM General Motors In the world of automotive repair specializations, we have a deep understanding and mastery of what it takes to give your vehicle the best possible performance and fuel efficiency. Today we will focus on 1998 AM General Motors models and discuss why…

-

250-24105 upstream and downstream oxygen sensors on 2001 Honda CR-V LX Cleaning and maintenance methods

Welcome to my automotive blog, where we delve into the intricacies of maintaining and optimizing your vehicle's performance. In this article, we will explore the crucial components of the 2001 Honda CR-V LX – the 250-24105 upstream and downstream oxygen sensors. I'll guide you through the significance of these sensors and provide expert tips on…

-

What are the benefits of having oxygen sensors in your car? What are the disadvantages of having oxygen sensors in cars?

With the continuous development of automotive technology, oxygen sensors have become an important part of the emission control system of modern vehicles. These compact sensors are located in the car exhaust system and are able to detect and measure the oxygen content in the exhaust. The introduction of oxygen sensors allows automotive engineers to more…

-

A Pack of 4 Oxygen Sensors Fit the Cadillac SRX? Cadillac SRX How About This Car?

If you own a Cadillac SRX, you may be wondering if a pack of 4 oxygen sensors will fit your car. The answer is yes, but it is important to ensure that the oxygen sensors you purchase are compatible with your specific make and model. Oxygen sensors play a critical role in the proper functioning…

-

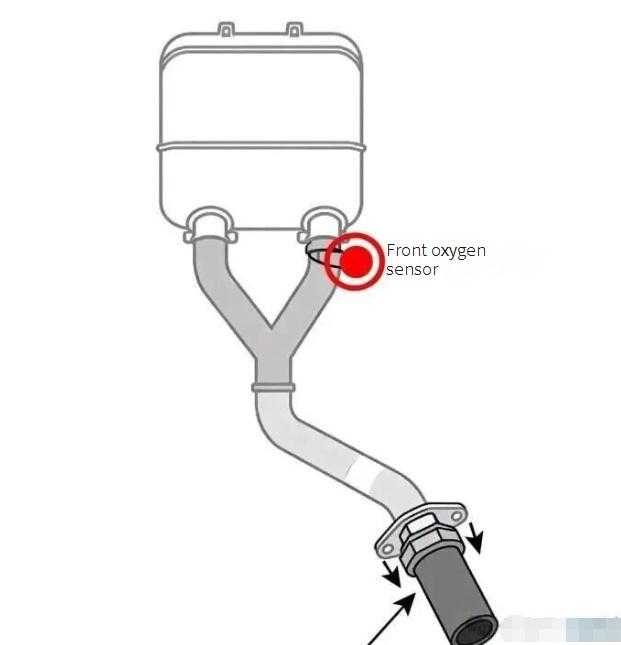

What's the Deal with Upstream and Downstream Oxygen Sensors?

If you're a car enthusiast or just someone who cares about their vehicle's performance, you may have heard the terms "upstream" and "downstream" oxygen sensors thrown around. But what do these terms actually mean? And why do they matter? Let's dive into the world of oxygen sensors and find out. First off, what exactly is…

-

What are the effects of high performance double layer protection, alumina hydrophobic layer, teflon filter, stainless steel housing for making oxygen sensors 234-5010?

If you're in the market for an oxygen sensor, you may have noticed the 234-5010 model. This particular sensor has gained popularity due to its high performance double layer protection, alumina hydrophobic layer, teflon filter, and stainless steel housing. But what do all these features actually mean for the effectiveness of the sensor? Let's break…